Range Rover Overland camper build diary : part 1

This is the diary of the extreme overland camper ‘DOGGER’

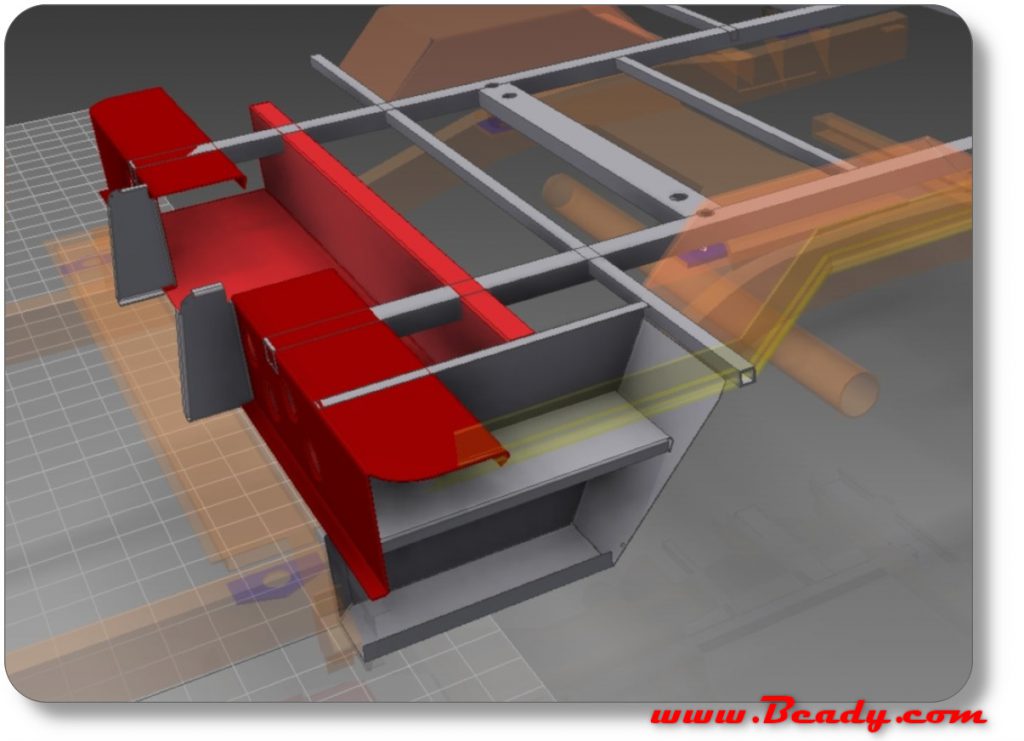

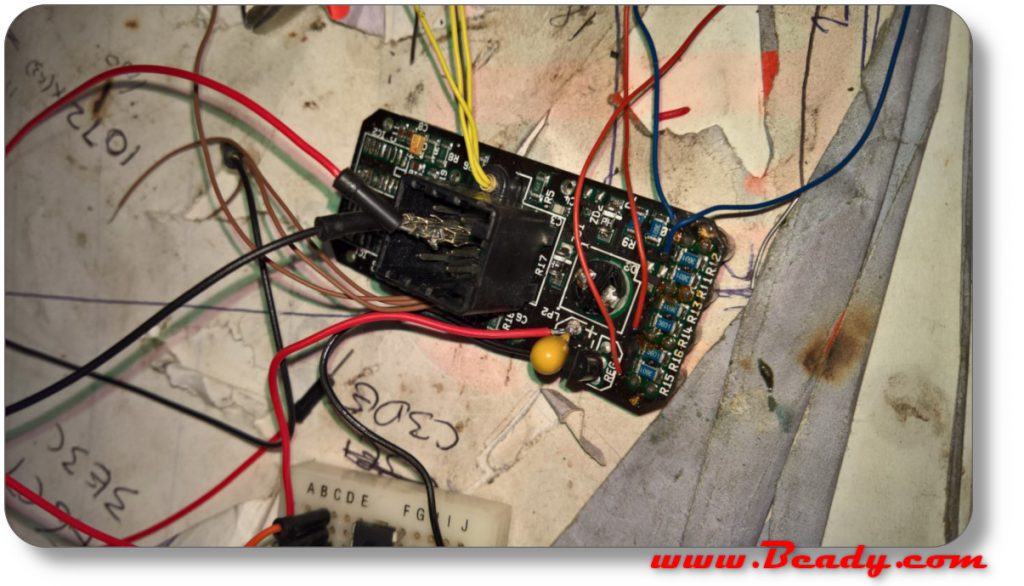

First came the CAD model, complete 100% including the standard P38 range rover was modelled in CAD and a custom visio template designed for the new wiring loom.

Everything was pre designed to the 1/10 millimetre, the build was in inches but hey ho that’s life 🙂

First get a range rover, the P38 cost 1200£ from ebay, L322 is Chris my Brother/Fabricator/and chief Sikaflex applier ( SWMBO doesn’t even let me paint the house)

we ran it around for a day then started work

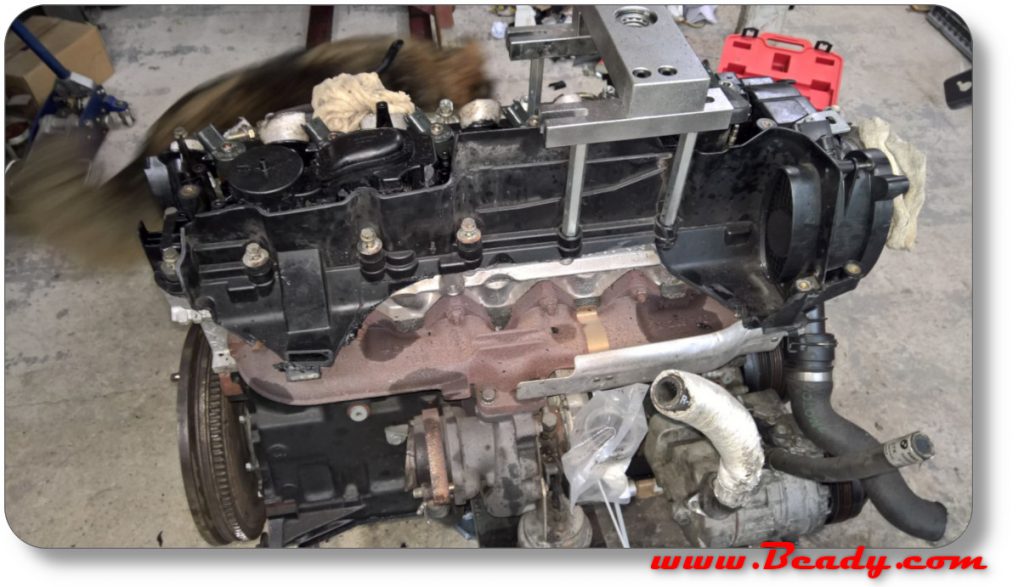

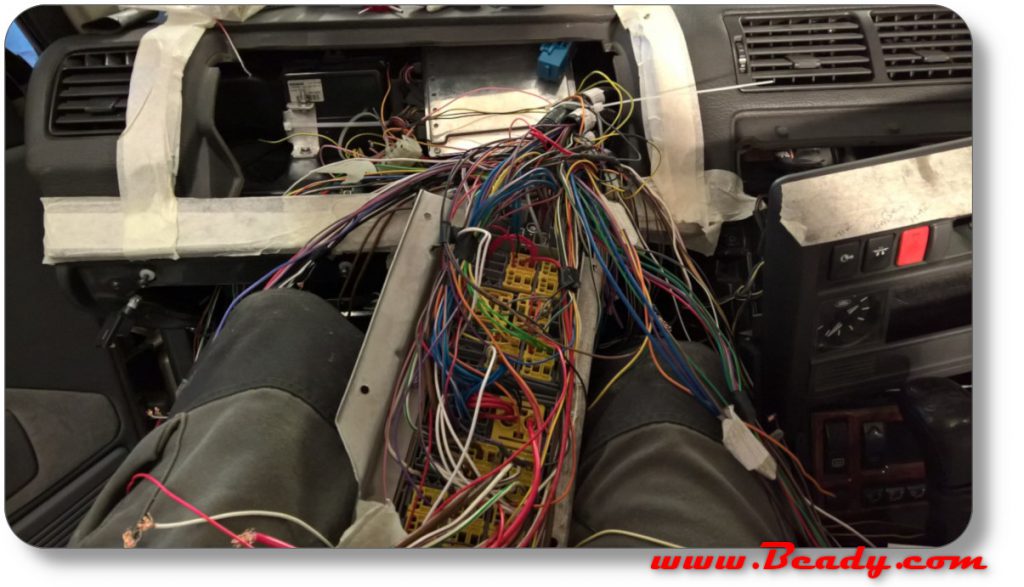

We ripped out the old 2.5 diesel and the entire wiring loom and all the ECU’s

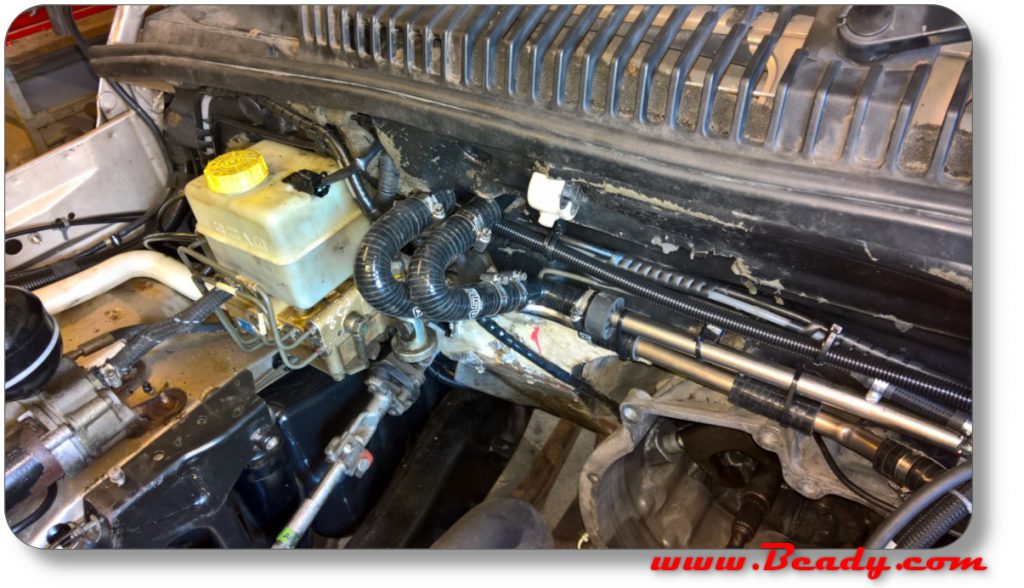

then moved the ABS ecu and the transfer box ecu up high behind the dash and placed the new BMW M57 ecu high also. The ECU has the immobiliser removed and a torque /High MPG map installed, we also carry a spare so we are never left for dead…maybe

There are nearly 1000 wires in the complete new loom

I reverse engineered the comms to the HVAC and dash display and made a bespoke BECM to make them work. including cruise control that’s built into the engine ECU.

The engine mounts from the old engine are a close fit , the right hand side has to be dropped on the chassis side for the turbo to fit nice.

Trouble removing injectors from the M57 engine , required a big puller which just snapped the injector in half :-(, the eventual engine I used was bought with no injectors so I knew they would come out, copper grease ensure they will again.

Everything fitted and ready for the new engine.

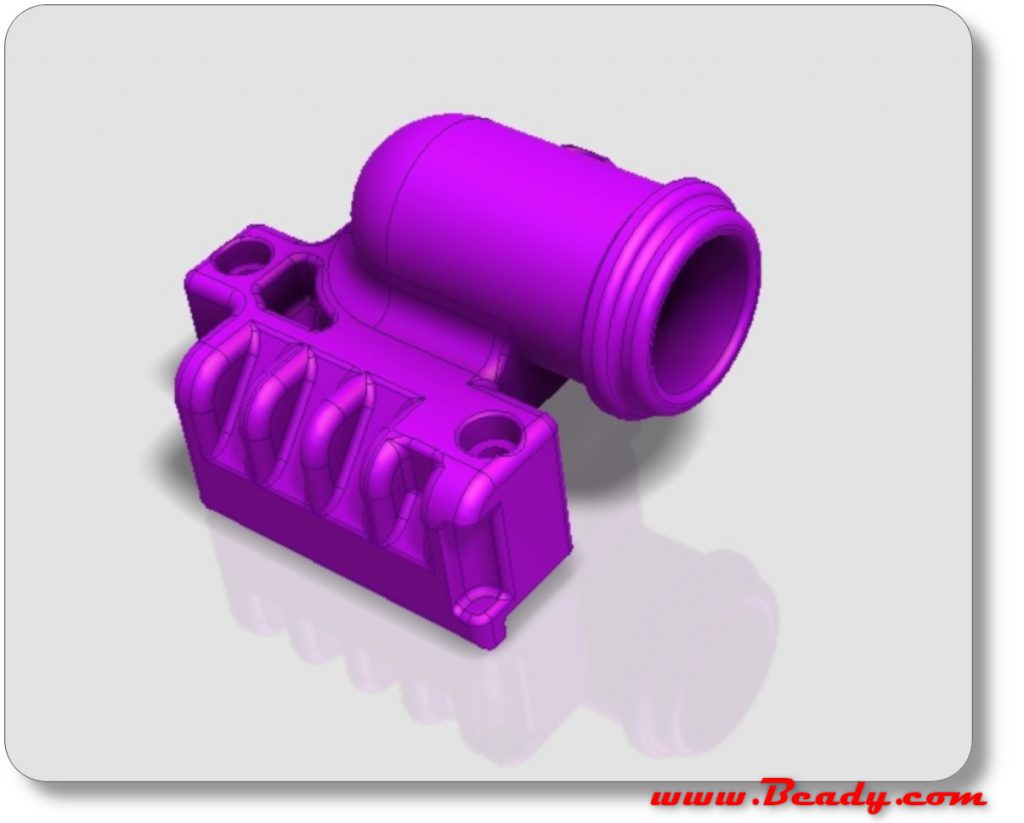

This is a custom plate between the gearbox and engine as used on our Dakar cars to ensure a tight seal for wading.

air box removed with a grinder and slitting disc.

3d printed crank case breather to adapt the breather after the airbox is removed , you can buy it here. and get lots more info about it here.

I thought it best to test the WEBASTO diesel heater and the engine water system before finalising the design. Thermal imaging camera helps with the setup

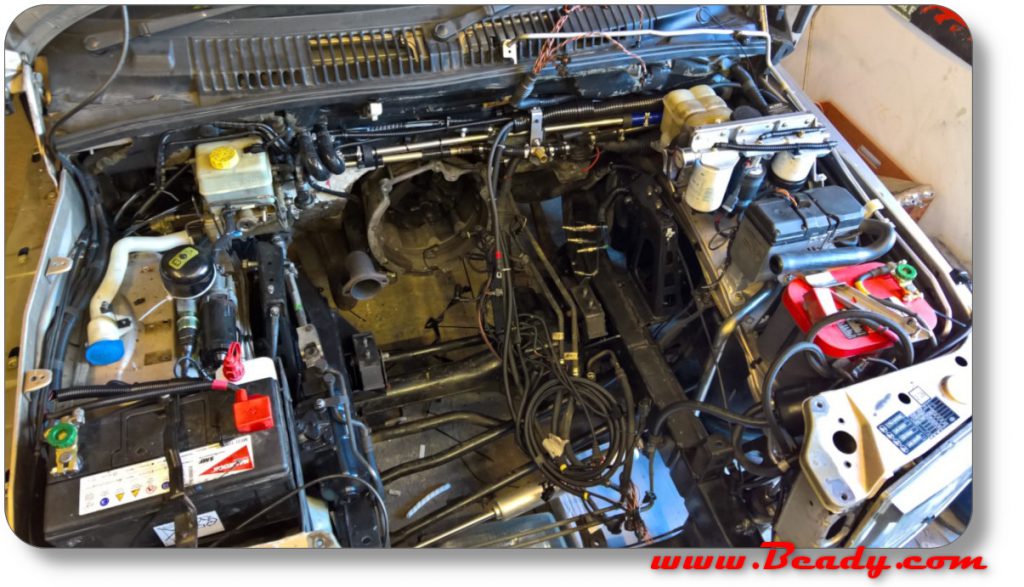

new M57 3 ltr diesel fitted, now to sort the air filter out and the snorkel.

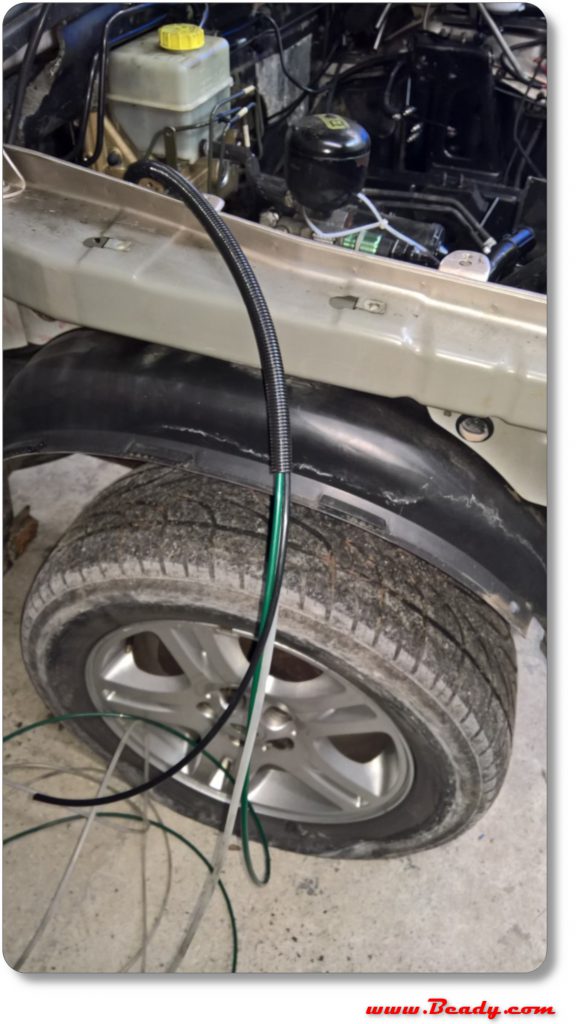

breather pipes for axles and diffs and gearbox, green for ARB lockers, white for fuel burning heater, they are colour coded, black are transmission breathers, green are the air lockers and clear is for the webasto cab heater

breathers routed into snorkel, this cap goes on the air filter and seals tight

back inside and the switch module is deleted and the interior switches converted to standard simple mode of operation, only two needed now, carbon effect covers the old holes

The Air suspension switch has been reprogrammed to work the Air compressor and ARB diff air lockers.

Finally started to gather all the wires into the new fuse box location

Custom fuse box finished, behind it is the ABS ecu and the engine ECU

The finished engine bay, P38 with M57 engine and everything else redesigned to fit correctly in the bay.

The custom front bumper is CAD designed , it fits the standard Range Rover and protects the washer bottle and A/C components neatly

it carries the Hi lift jack and down the front is the Tirfor winch rope

Hot dip galvanized, we did this on Merlin our old 4×4 truck camper and after 17 years there was zero rust, its worth the effort.

first fit and it looks good.

Hello friend please pass for zip file for front bumper Thanks great project you made .

http://www.beady.com/BigFileForBlog/Beady.com_P38_bumper_DWG_drawings2.zip

password

http://www.beady.com/blog/beady/

Hi Beady,

I am very impressed with your build and am currently in the process of building my own P38 camper to take on a trip around the world. I have bunch of questions that it would be nice if I could email you about but I could not find an address anywhere 🙂

Since this form requires me to provide mine, I sincerely hope you will contact me through there.

sent you an email 😉

your website is down

Hi, I’m building a similar expedition car project. I used an engine from e39 and a gearbox from e46 330xd manual 6q. I’m not entirely sure about the engine mounting. I used the right engine mount under the turbo from the m51 engine, the left one I have to make a new one. But when I look at the oil pan, it’s very close to the differential. I wonder if you had to adjust the oil pan as well?

Hi Marek,

I think my engine mounts were from an E46, I had to remake make both. They are not pretty but work, maybe I will revisit them one day.

yes you have to modify the sump.For some reason I didn’t take any pictures of the mods 🙁

Hi.

Does the engine swap requires modification of engine mounts or gearbox bell? Or is it just “take out old engine, insert new one”?

I think about putting m57d30 (no turbocharger) instead of m51, because getting good second-hand m51 is almost impossible nowdays.

Regards.

Arek

The M57 will bolt onto the bell housing with no modifications, Engine mounts need modifying, all the other parts, exhaust , water pipes etc are very close

put the OE water temp sensor in the top rad hose ( the one from the centre of the head, this is easiest way to get the gauge working, also use an X5 or range rover Td6 engine loom then the ECU fits easy in the same location as the M51 ECU

enjoy the journey, you will definitely like the extra torque

bd

Hi.

Thank you for explaining. I was afraid that engine mount will be issue here. Unfortunately mechanics newer was my strong side 🙁

Arek

Beady can ask you about your diesel filters please, it looks like you have a pump there too? Regards.

This pump setup is not the most ideal that I would have liked , room for the filters was the problem, the rule for fuel is ‘never suck’ and this is especially true of common rail diesels, you get micro bubbles in the fuel that compress in the HP pump and make the rail pressure vary.

so why did I lift the fuel like this.

the setup is as follows

remove the pump from the fuel tank ( P38 in tank pump requires the dropping of the tank to repair, not good if it packs up and your stuck in a hole)

remove the prefilter in the tank, sometimes called the sock, this is so all water and dirt can carry thru the fuel line to the first filter

the first filter has a clear glass bowl and a 9 micron cellulose filter that removes water

next is a electric fuel pump, protected by the first filter

second is a ultra fine 6 micron filter.

having the pump this high made the pump whine, so I fitted a second pump and a inline race filter with a washable gause filter under the floor, the fuel system is now very quiet and both pump only draw roughly the same current as a single one, the new pump under the floor is protected to a degree from large debris by the Sytec filter and if it fails it is easy to bypass.

on the Dakar cars we have a sump system with dual fuel pumps & filters under the floor, but with these cars we design the fuel tank and entire car from scratch with this in mind. The sump system is the best method and most reliable , although repairs to the fuel system mean lying on your back under the sill of the car.

the fuel filter heads are Donaldson

Donaldson filters

I hope this info is helpful for you.

Hi Beady, I’ve just binged on the whole job this afternoon, very impressive! I have a couple of queries if you don’t mind, …. engine wise you seem to have had a couple of failures but basically seem to be sticking with the early style and the DDE4 system? Do you favour it for particular reasons or is it just a question of availability? I ask because old E60’s seem better value here but I don’t want to make life difficult (mine is a P38 2.5 DHSE auto).

And you did mention a high torque re-map which would be of interest, is that available to buy?

Hi Rob, sorry about slow reply.

I went with the DDE4 for various reasons, one was the lack of availability of narrow block DDE5 engines, the DDE5/306D2 is a better engine and I now have a nice low mileage example sat outback. The early engine fails were due to a oil pickup pipe error, very costly and annoying.

The 306D2 doesn’t suffer from dead injector issues and is much better in the cooling front, the DDE4/306D1 can overheat when really pushed, it also has much more power, so when detuned can give better MPG.

The 306D2 can easily have monster power and torque 285bhp/800nm , but the p38 autobox will not take it, the transfer box and axles are fine.

The 306D2 is only available in narrow block form on the last of the E46 in the UK that was 2003 models, all others are wide block, you can convert if you are skilled enough.

see my post on autobox comms,

I did work out the 4.6 comms and it woud be interesting to see if the later ecu for the thor V8 auto that uses CAN would work without any adaption from the dde5 ecu.

if you have to do mods to the bell housing then it might be be worth using the bigger later gearbox from the 4.6.

and R.E. the hi torque remap, if you are using the standard gearbox then a standard RR TD6 map is enough, it won’t mash the box, and you will notice a huge difference in driving compared to the M51, basically it drives like the 4.6 but with 2.5D MPG

Hi Mate. Im keen on your bumper design as well, as Im getting a P38 soon as well. Im reading and rereading each piece…but no luck reg password :-((

Any chance of your help?

Ta

PS: Great built, lots of fantastic design ideas and solutions.

use Search at the top , or try BEADY

Any plans to fabricate and sell the front bumper?

Yes and No, family and friends have asked for one, it is in full CAD so is easy to replicate, fits on standard 2.5 , not sure about 4.6/4.0 if the cooler is in the way on the left.

but….

the spec is high , just the 6082 alloy centre shield is £110 !! ( probably halve that in 1050 spec, but not as good) , It would probably end up to expensive,

but if you wanted I could post up the drawings and CAD model and then people could make it themselves.

Hi,

Can you share us the front bumper cad file? Looks pretty 🙂

Here you go, sorry about the zip password but stops the google spider stealing everything other people make.

you may need some more sketches for how it goes together, it requires some 25mm equal Angle for the centre bars.

bd

Thank you!