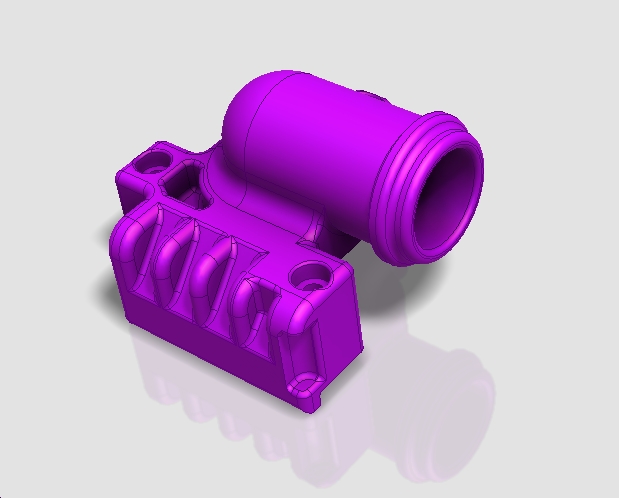

When converting the BMW 6 cyl diesel into other cars the air box can be removed like this How to cut a BMW M57 air box If you are having...

Month: January 2016

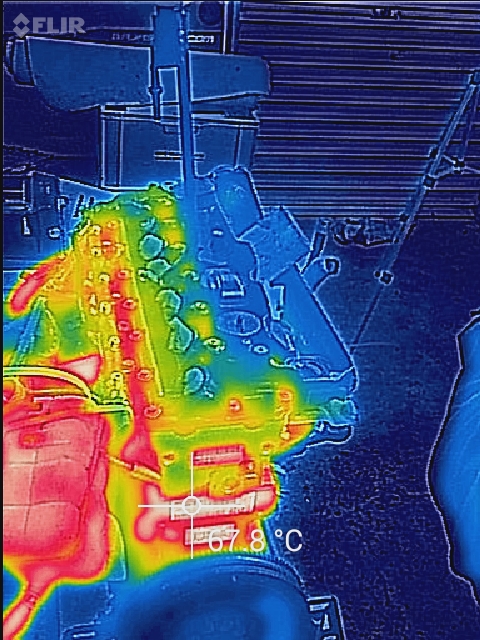

while testing the FBH, (fuel burning heater) on the engine while it is still on the cradle in the workshop I thought it would be a good time to test my...

on the P38 camper conversion, the spec requires locking differentials with an air compressor of the ARB style, not wanting to stick the big ARB/Carling type switches in the dash...